Catalogues Generator

Catalogues Generator

Automatic Generation of Catalogues and performance Tables

This feature allows the automatic creation of catalogues and performance tables in Excel format. This feature permits to design a series of coils, unit coolers, air coolers, remote condensers, dry coolers, condensing units, motorevaporators, etc.. and insert a capacity table , calculated at different working conditions in the catalogue of the new series.

Advantages of this new feature:

- Within minutes you can create tables of a hundred units

- The tables can be saved in Excel already formatted and ready for use

- Three tables are generated: capacity, air side pressure drops and pressure drops fluid side

- Working conditions are fully customizable

- The units of measurement are customizable

- Possibility to save the project of the catalogue to a file and to update the data later if needed, simply load the project and create new catalogue

How to use this new function

Choose the menu “Calculate” →

On the top left end of the grid let’s insert the project files of models we need to create the catalogue for.

For each model we have already created a Coils project. To expedite this, just follow a simple procedure at the end of this section.

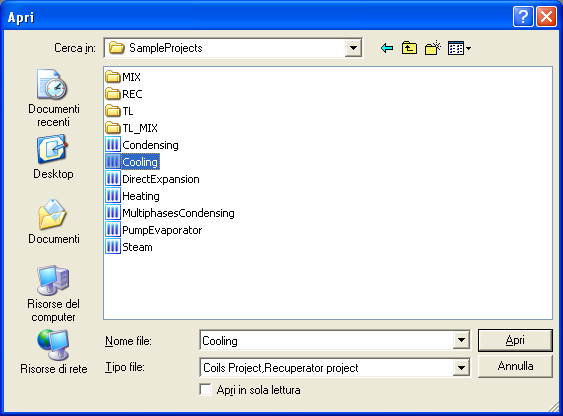

Let’s click on  on the top right corner of the grid and we specify the project file to insert in the list:

on the top right corner of the grid and we specify the project file to insert in the list:

Attention: the projects need to be in the same calculation modality!

It is necessary to specify the name of the model/size that corresponds to this project. Thus we write the name in the column “Model Description”.

And repeat the same above procedure for the introduction of the other models.

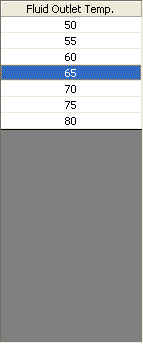

In the grid at the top right hand side we insert the temperature, which will be included in the columns of the Excel file. These temperatures vary depending on the calculation modality:

Heating: Inlet Fluid Temperature

Cooling: Outlet fluid Temperature

Condensing: Condensing Temperature (Middle Point)

Evaporating: Evaporating Temperature (Middle Point)

Vapour: Saturation Temperature

Pump Evaporator: Evaporating Temperature (Middle Point)

Let’s click on the green button “+”  on the left hand of temperatures grid more than once we introduce these values:

on the left hand of temperatures grid more than once we introduce these values:

Below we can find the delta T (temperature difference): in case of fluids without phase change, dT refers to the temperature difference between the input and output fluid side, in case of fluids with phase change, dT refers to the difference between the temperature fluid side and the input side air. Here are some examples:

Modality |

Temp. Fluid Side |

Delta T |

Set Value |

Results |

Heating |

80 |

10 |

Outlet Temp. |

70 |

Cooling |

12 |

5 |

Inlet Temp. |

7 |

Condensing |

45 |

15 |

Inlet Air Temp. |

30 |

Evaporating |

5 |

6 |

Inlet Air Temp. |

11 |

Vapour |

120 |

100 |

Inlet Air Temp. |

20 |

Pump Evaporator |

5 |

6 |

Inlet Air Temp. |

11 |

Let’s set a delta T of 10 °C

![]()

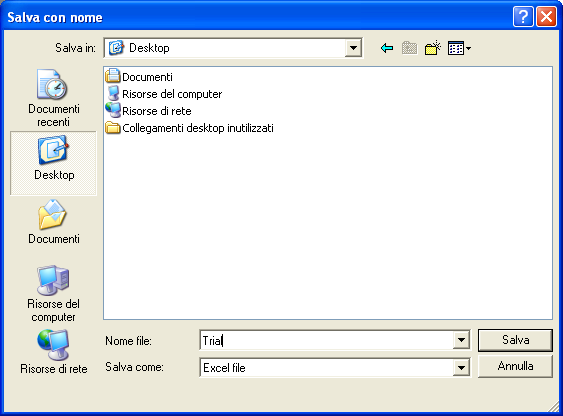

Once the temperatures are set, we specify the path on which we save the Excel file by clicking on  with the disk “Output Excel file”

with the disk “Output Excel file”

.

.

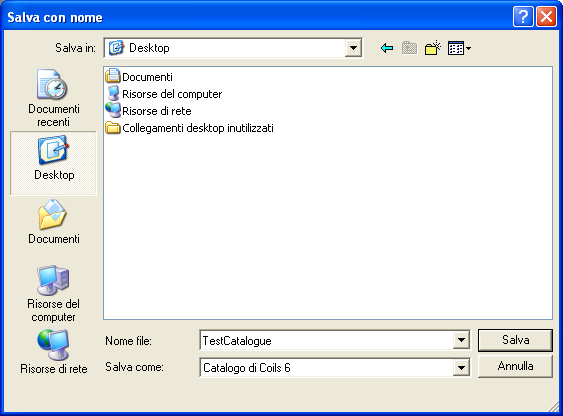

Now that the project is ready, let’s click on the  to save work done so far:

to save work done so far:

Attention: this operations saves the information contained in this mask, not the performance table, the pressure drop, etc..

Let’s generate the catalogue  and let’s wait on the software to finish the data generation.

and let’s wait on the software to finish the data generation.

Considerations and limitations

- Projects must all be set in the same calculation mode. Cannot be mixed the projects made in direct expansion, cooling or condensation modes.

- The working conditions of the coil must be the same for each project. For example, if we calculate a set of DX-coils, overheating and subcooling values must be the same for each project, otherwise the performance data will not be comparable. The same goes for: fluid selected, relative humidity / wet bulb temperatures, fouling factor, factor recycling, etc..

- In the direct expansion mode is possible to vary the temperature of evaporation, but not the pressure, in addition the calculation is performed at a constant condensing temperature of 45 ° C.

- In condensing mode, the evaporating temperature is fixed: 2 ° C

How to generate a set of project files, one for each unit

- Create a new project of 6 coils in the desired mode

- Set the working conditions of the first unit: temperature and relative humidity on the air side, air flow, fluid inside the tubes, inlet temperature / outlet or evaporation / condensation, etc..

- Set construction data of the coil of the first unit: geometry, number of rows, number of circuits, step fins, finned pack size (length), presence or absence of the manifolds

- Perform the calculation and display the print preview

- Verify that the data are correct and match the performance data of the first unit

- Make corrections if necessary

- Save the project and specify a file name similar or equal to that of the unit

- Change the data construction of the coil by putting those in the second unit

- Click on "File", then "Save As"

- Specify the file name as that of the second unit

- Repeat the steps from 8 onwards for each unit